Whispers of Kosse’s Past All Hail the King

Before the Civil War, America had a king…King Cotton. Cotton fields stretched as far as the eye could see all over the deep South, including Texas. Cotton was highly profitable as it provided a cheaper alternative to silks and other expensive fabrics; and a cooler one than wool.

Obviously, the profitability of cotton took a serious hit after slavery was abolished and former slaveholders had little alternative than to pay the people who processed the crops. Likewise, much of the country that had been used to farm vast acres of cotton had been devastated by battle and the arrival of the carpetbagger. Many formerly wealthy plantation owners no longer had the means to pay the taxes on their lands and so moved west and began again.

Cotton had been grown in Texas along with grain crops for many years before the Civil War. After it, a new influx of farmers expanded the market exponentially. Gins and seed oil companies began springing up in every community with Galveston being the main shipping terminal for all things cotton.

Kosse had many gins over the years, both within and without the city limits. Before the rail lines came, farmers would load wagons and ship the cotton by mule team to the nearest railhead. From there it would be weighed and sent to places like Galveston to be processed. Once Kosse’s gins were operational, farmers could be paid for their goods right in their own hometown.

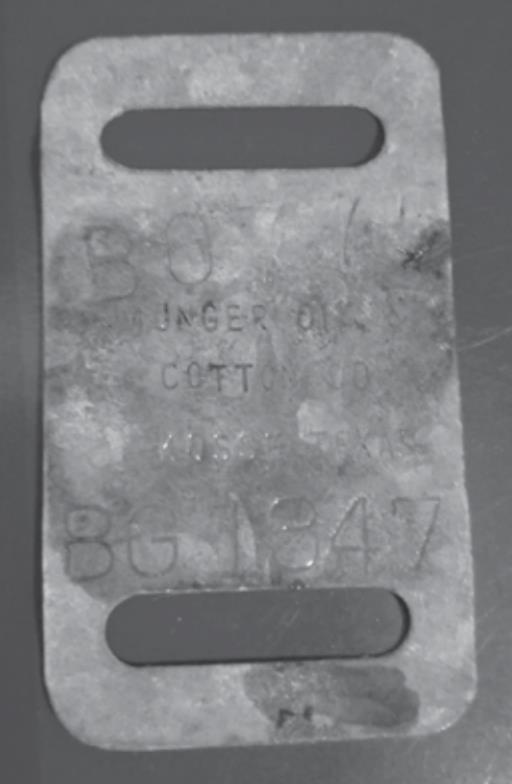

Some of the gins that we know of in the Kosse area are the Kling, Munger, Whitlow, and Gunter Gins. The Kling was located on N. Narcissus St., the Munger on S. Narcissus St., the Gunter on Adams, and the Whitlow was located one mile west of Kosse. The longest-running gins were the Kling and the Munger. The Whitlow gin burned to the ground in 1895 due to a match being thrown into the seed cotton while the gin was running.

Cotton was packed into bags in the field, which were transported to the gin by wagon. Once there, the bags were weighed and tallied. From here the cotton would be fed into the gin where the seeds were separated from the lint using huge saw blades. The seeds would drop down into a chute and the lint would be conveyed to a separate area.

The lint would then be taken to a baling box where it would be compressed into bales weighing anywhere from 400 to 500lbs. The seeds would be either sold to reproduce the next crop or sent to a refinery to be pressed to produce seed oil. Cotton yards sprung up along the railroad tracks that passed through Kosse. One was located where the Kosse Volunteer Fire Station now stands.

Some of the older folks in Kosse remember picking cotton in the fields and even riding on top of the bales on the way to the gin. Jack Foshee shared some stories regarding the Kling gin and the dangers of this profession.

As a young boy, Jack recalls: “Booge Mitchell ran the 1st Munger and the Kling gins. He used to live there in the house close to the water tower. There was a big tank that we called the cooling tank. It was used for cooling those steam engines. That old steam engine, I remember him going out there and firing them up, and boy they would send up smoke! The smoke made big smoke rings.”

Mr. Foshee also spoke about the dangers of working the gins: “The Klings, they had a son that lost an arm in the gin. There were two men, Hester Price, and Heg Kling that lost arms in that gin. The cotton would get bound up and you’d have to clear it to keep the gin running. There were big saw blades in there to separate the seeds from the cotton. My grandfather would always use a stick to clear it, but Heg, his sleeve got caught and pulled him right into those blades.”

In 1883, a Kosseite named J.D. Flanagan filed for a patent on an improvement of this feature of the gin. In his application, he cited the frequency of the cotton becoming bound up, and so he invented what he thought was a more efficient and safer seed separating mechanism. The patent was granted for his lifetime only. In 1886, a Kosseite named W.S. Bryan filed an improvement to the machinery of the baling boxes at gins. It involved a mechanism to pack the cotton more compactly in order to make it applying baling wires or bands to the bales easier. This too was a lifetime only patent. Copies of these patents can be seen at the Kosse Heritage Society.

Not only were men trying to improve the machinery and processes for cotton, but they also held their own with market pricing as well. An article published in the Liberty Vindicator; September 7, 1894 details a response from the cotton farmers of cotton to low pricing instituted by the larger refining operations in Texas. The four largest cotton processing companies had banded together to increase their profits by paying farmers less than the market price for their crops.

The farmers of Kosse united and instituted a trade agreement of their own during a meeting at the Kosse Opera House. They agreed to hold all seed until prices came up to a fair price, encouraged farmers to sell to local mills who were paying higher prices, and agreed not to sell for less than $10.00 per ton. This trade agreement was posted in newspapers across the state, with many other communities; including Eureka; instituting similar policies.

Cotton was a huge part of the town’s economy for many years. Not much remains of the gins from Kosse’s past today. The Kling gin has some concrete features that are still visible, but of the rest nothing remains but photographs, memories, and a few small artifacts.